CUSTOM OUTBOARD ENGINE BRACKETS

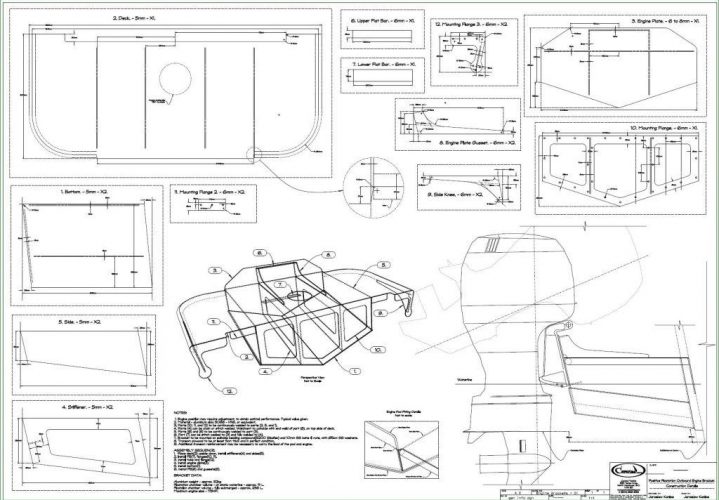

Drawing Description

Assembly Drawings:

(for detailed construction study only)

$50CAD

1. Assembly Drawings.

2. Parts List.

3. Nest.

4. The use of cutting files-CNC cutting.

$500CAD

Please enquire

1. All plate parts, cut and formed.

2.Assembly drawings.

*Does not include tubing, cleats etc.

**Pending current price check at time of purchase

tbd.

Please enquire

General Information about Outboard Engine Brackets

Why does it make sense to install a positive floatation engine bracket?

- It creates more room in the boat by moving the outboard engine behind the transom.

- Longer force arm gives the boat easier handling.

- Longer force arm also means a better “hole shot” – shorter time to plane.

- The propeller works in a less disturbed water flow, further behind the transom, which results in better efficiency; this means

better fuel economy, and a bit more speed. - Integral transom platform allows easier boarding.

- The positive floatation chamber fully compensates for shifting the engine weight aft, and can even add a little extra buoyancy,

if required. - It is important not to confuse an offset engine bracket, as it is described above, with a bottom extension bracket, which has

some of the same advantages, but not all. Since the bottom extension adds more wetted surface, it creates additional friction drag. In an offset bracket, when the hull is planing, the bracket does not touch the water.

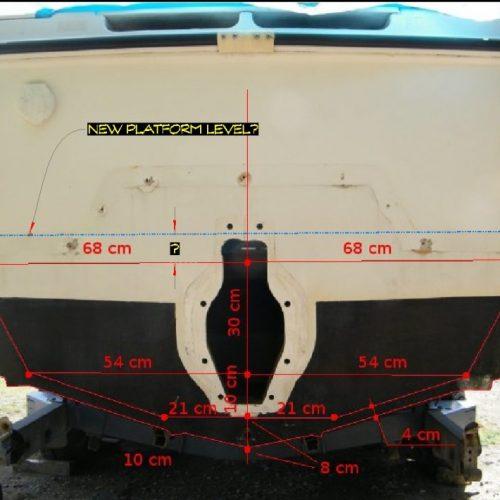

- Here is the list of bracket parameters that we can custom adjust to your hull:

- Transom angle.

- Engine shaft length.

- Floatation chamber volume and shape – calculated to achieve the desired trim.

- Bracket fore and aft depth.

- Engine plate angle and shape.

- Bracket platform width.

- Bracket platform corner radius.

- Bracket platform corner tube diameter(other edge profiles possible).

- Flat or curved transom.

- Two versions: weld-on for aluminum boats,

and bolt-on for fibreglass, or wooden boats. - Single or multiple – 2, 3, 4 engines, installations.